General information about sealed radioactive sources in industry

There’s wide range of application of radioactive sources in different fields of industry, technology and science.  They are mostly used as radiation generators, producing X-Ray radiation, electron and neutron beams, as well as alpha, beta, gamma radiation and neutrons produced by radioactive decay. Most used industry applications, using sealed radioactive sources are non-destructive testing of materials – defectoscopy, probes and indicators, such as hygrometers, hydrometers, thickness meters and other kinds of analyzers using mainly gamma, beta radiation and neutrons, logging works in bore holes for geological purposes, X-ray fluorescent analysis and methods of activation analysis, industrial irradiators of gamma beams, ion generators, flame ionization detectors – FID, chromatographs and others.

They are mostly used as radiation generators, producing X-Ray radiation, electron and neutron beams, as well as alpha, beta, gamma radiation and neutrons produced by radioactive decay. Most used industry applications, using sealed radioactive sources are non-destructive testing of materials – defectoscopy, probes and indicators, such as hygrometers, hydrometers, thickness meters and other kinds of analyzers using mainly gamma, beta radiation and neutrons, logging works in bore holes for geological purposes, X-ray fluorescent analysis and methods of activation analysis, industrial irradiators of gamma beams, ion generators, flame ionization detectors – FID, chromatographs and others.

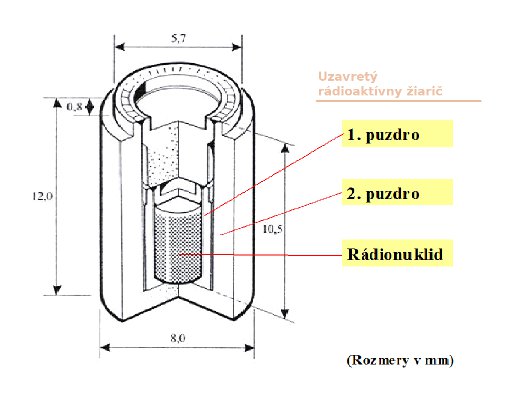

Technical description of sealed radioactive source

Each radioactive source that is used on an industrial probes and technology, is enclosed in a stainless steel capsule, that prevents the leakage of radioactive particles from the radioactive source to surrounding environment.

The recommended lifetime of radioactive sources is indicated in a certificate by the manufacturer or in a accompanying documentation. This lifetime period does not indicate the lifetime of the radionuclide rather it characterize the lifetime of the steel capsule, which prevents the leakage of radioactive particles into the surrounding environment.The damage of capsule is caused by natural oxidation of metallic materials which could be caused by external influences such as atmospheric humidity, environmental temperature, dust and internal damage due to constant radioactive decay of the substance in the capsule.

The recommended lifetime of radioactive sources is indicated in a certificate by the manufacturer or in a accompanying documentation. This lifetime period does not indicate the lifetime of the radionuclide rather it characterize the lifetime of the steel capsule, which prevents the leakage of radioactive particles into the surrounding environment.The damage of capsule is caused by natural oxidation of metallic materials which could be caused by external influences such as atmospheric humidity, environmental temperature, dust and internal damage due to constant radioactive decay of the substance in the capsule.

Maintenance of radioactive sources after their recommended  lifetime requires more frequent intervals of the leakage rate tests (under current valid legislation of the Slovak Republic every 12 months long-term stability test), but this still doesn’t ensure that the source is 100% safe. In case of damage of the source, it may contaminate the environment, technological line of production, or workers in direct contact with this leaking source. Decontamination of these materials, lines and workers will surely costs the company much more than change of the source which is close to the end of its lifetime period.

lifetime requires more frequent intervals of the leakage rate tests (under current valid legislation of the Slovak Republic every 12 months long-term stability test), but this still doesn’t ensure that the source is 100% safe. In case of damage of the source, it may contaminate the environment, technological line of production, or workers in direct contact with this leaking source. Decontamination of these materials, lines and workers will surely costs the company much more than change of the source which is close to the end of its lifetime period.